Umgaqo wethu osisikhokelo kukuhlonipha uyilo lwangaphambili lomthengi ngelixa sisebenzisa amandla ethu okuvelisa ukwenza iiPCB ezizalisekisa imilinganiselo yomthengi. Naluphi na utshintsho kuyilo lokuqala lufuna imvume ebhaliweyo evela kumthengi. Emva kokufumana isabelo sokuvelisa, iinjineli ze-MI zivavanya ngokucophelela onke amaxwebhu kunye nolwazi olunikezwe ngumthengi. Bakwachonga nakuphi na ukungangqinelani phakathi kwedatha yomthengi kunye nobuchule bethu bokuvelisa. Kubalulekile ukuqonda ngokupheleleyo iinjongo zoyilo lomthengi kunye neemfuno zemveliso, ukuqinisekisa ukuba zonke iimfuno zichazwe ngokucacileyo kwaye ziyakwazi ukusebenza.

Ukuphucula uyilo lomthengi kubandakanya amanyathelo ahlukeneyo afana nokuyila isitaki, ukulungelelanisa ubungakanani bokomba, ukwandisa imigca yobhedu, ukwandisa ifestile yemaski ye-solder, ukuguqula iimpawu efestileni, kunye nokwenza uyilo loyilo. Olu hlengahlengiso lwenziwa ukulungelelaniswa neemfuno zemveliso kunye nedatha yoyilo yomthengi.

Inkqubo yokudala i-PCB (iBhodi yeSekethe eShicileleyo) inokuchithwa ngokubanzi ibe ngamanyathelo amaninzi, ngalinye libandakanya iindlela ezahlukeneyo zokuvelisa. Kubalulekile ukuqaphela ukuba inkqubo iyahluka ngokuxhomekeke kwisakhiwo sebhodi. La manyathelo alandelayo achaza inkqubo ngokubanzi yePCB enamaleko amaninzi:

1. Ukusika: Oku kubandakanya ukucheba amaphepha ukuze kusetyenziswe kakhulu.

2. I-Inner Layer Production: Eli nyathelo ngokuyintloko kukwenza isiphaluka sangaphakathi se-PCB.

- Unyango lwangaphambili: Oku kubandakanya ukucoca umphezulu we-PCB substrate kunye nokususa naziphi na izinto ezingcolisa umphezulu.

- Lamination: Apha, ifilimu eyomileyo inamathele kumphezulu we-PCB substrate, ilungiselela ukuhanjiswa komfanekiso olandelayo.

- Ukubonakaliswa: I-substrate edibeneyo ibonakaliswe ekukhanyeni kwe-ultraviolet usebenzisa izixhobo ezikhethekileyo, ezidlulisela umfanekiso we-substrate kwifilimu eyomileyo.

- I-substrate evezwayo iphuhliswa, ifakwe, kwaye ifilimu isuswe, igqibezela ukuveliswa kwebhodi yangaphakathi yangaphakathi.

3. Ukuhlolwa kwangaphakathi: Eli nyathelo ngokuyintloko kukuvavanya nokulungisa iisekethe zebhodi.

- Ukuskena okubonakalayo kwe-AOI kusetyenziselwa ukuthelekisa umfanekiso webhodi ye-PCB kunye nedatha yebhodi esemgangathweni ukuchonga iziphene ezifana nezikhewu kunye nezibonda kumfanekiso webhodi. - Naziphi na iziphene ezifunyenwe yi-AOI ziye zilungiswe ngabasebenzi abafanelekileyo.

4. Lamination: Inkqubo yokudibanisa iileya ezininzi zangaphakathi kwibhodi enye.

- I-Browning: Eli nyathelo liphucula ibhondi phakathi kwebhodi kunye nentlaka kwaye iphucula ukumanzi komphezulu wobhedu.

- I-Riveting: Oku kubandakanya ukusika iPP kwisayizi esifanelekileyo ukudibanisa ibhodi yangaphakathi yebhodi kunye nePP ehambelanayo.

- Uxinzelelo lobushushu: Iileya zicinezelwe bubushushu kwaye ziqiniswe zibe yiyunithi enye.

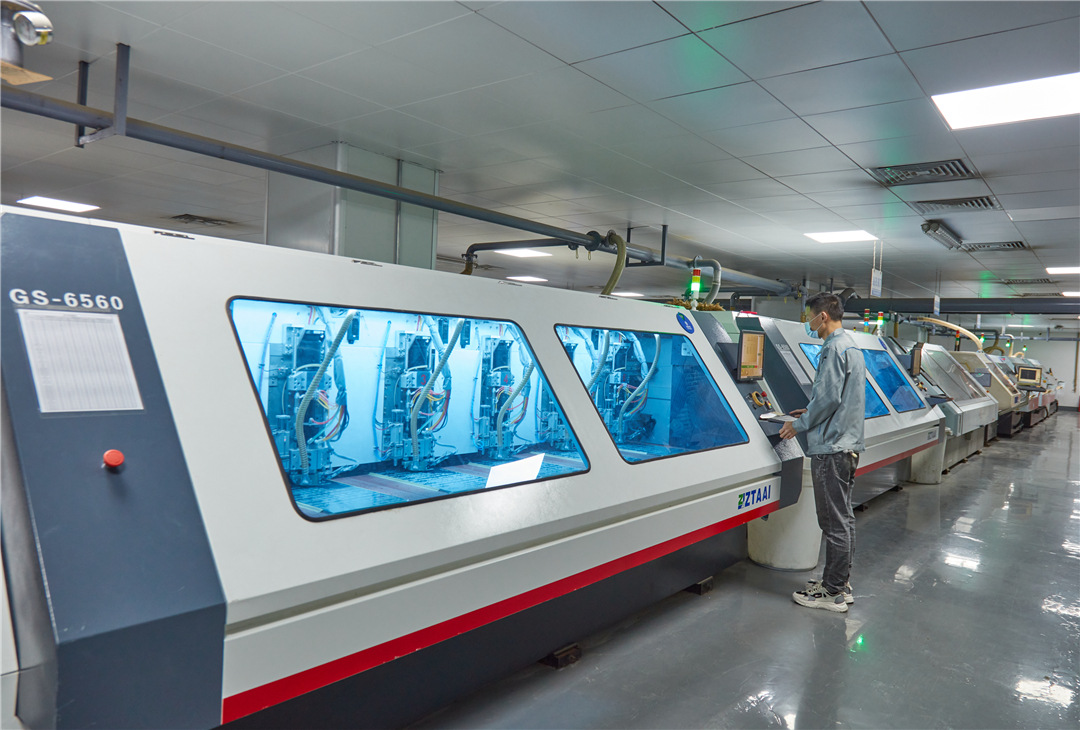

5. Ukugaya: Umatshini wokugaya usetyenziselwa ukudala imingxuma yobubanzi obuhlukeneyo kunye nobukhulu ebhodini njengoko kuchaziwe kumthengi. Le mingxunya iququzelele ukusetyenzwa kwe-plugin elandelayo kunye nokunceda ukutshatyalaliswa kobushushu kwibhodi.

6. I-Plating Copper Plating: Imingxuma egrunjiweyo ebhodini ifakwe ubhedu ukuze kuqinisekiswe ukuqhuba kuzo zonke iileyile zebhodi.

- Ukukhupha i-burrs: Eli nyathelo libandakanya ukususa i-burrs kwiincam zomngxuma webhodi ukunqanda ukucolwa kobhedu okulambathayo.

- Ukususwa kweGlue: Nayiphi na intsalela yeglue ngaphakathi komngxuma iyasuswa ukuze kuphuculwe ukubambelela ngexesha lokuxutywa kwe-micro-etching.

- I-Hole Copper Plating: Eli nyathelo liqinisekisa ukuqhuba kuzo zonke iileya zebhodi kwaye kwandisa ubukhulu bobhedu.

7. I-Outer Layer Processing: Le nkqubo ifana nenkqubo yangaphakathi yangaphakathi kwinqanaba lokuqala kwaye yenzelwe ukuququzelela indalo yesekethe elandelayo.

- Unyango lwangaphambili: Umphezulu webhodi ucocwa ngokucolwa, ukucolwa, kunye nokomiswa ukuze kuphuculwe ifilimu encamatheleyo eyomileyo.

- Lamination: Ifilimu eyomileyo inamathele kumphezulu we-PCB substrate ukulungiselela ukudluliselwa komfanekiso olandelayo.

- Ukubonakaliswa: Ukubonakaliswa kokukhanya kwe-UV kubangela ukuba ifilimu eyomileyo ebhodini ingene kwi-polymerized state kunye ne-unpolymerized state.

- Uphuhliso: Ifilimu eyomileyo engenapolymerized iyachithwa, ishiya isithuba.

8. Ukufakwa kweCopper yesibini, i-Etching, i-AOI

- I-Secondary Copper Plating: Iphethini ye-electroplating kunye ne-chemical application copper yenziwa kwiindawo ezikwimingxuma engagqunywanga yifilimu eyomileyo. Eli nyathelo likwabandakanya ukuphuculwa ngakumbi kwe-conductivity kunye nokuqina kobhedu, kulandelwa yi-tin plating ukukhusela ingqibelelo yemigca kunye nemingxuma ngexesha lokudibanisa.

- I-Etching: Isiseko sobhedu kwifilimu eyomileyo yangaphandle (ifilimu emanzi) indawo yokunamathisela isuswa ngokuchithwa kwefilimu, i-etching, kunye neenkqubo zokuqhawula i-tin, ukugqiba isiphaluka sangaphandle.

- I-Outer Layer AOI: Ngokufana nomgangatho ongaphakathi we-AOI, i-AOI yokukhangela i-optical scan isetyenziselwa ukuchonga iindawo ezineziphene, ezithi ke zilungiswe ngabasebenzi abafanelekileyo.

9. Isicelo seMaski ye-Solder: Eli nyathelo libandakanya ukusebenzisa imaski ye-solder ukukhusela ibhodi kunye nokuthintela i-oxidation kunye neminye imiba.

- Unyango lwangaphambili: Ibhodi ithatha i-pickling kunye nokuhlamba kwe-ultrasonic ukususa i-oxides kunye nokwandisa uburhabaxa bobhedu.

- Ukushicilela: I-inki yokuxhathisa i-Solder isetyenziselwa ukugubungela iindawo zebhodi ye-PCB ezingadingi i-soldering, inika ukhuseleko kunye nokugquma.

- Ukubhaka kwangaphambili: I-solvent kwi-inki ye-mask ye-solder yomile, kwaye i-inki iqiniswe ekulungiseleleni ukuvezwa.

Ukuvezwa: Isibane se-UV sisetyenziselwa ukunyanga i-inki yemaski ye-solder, okukhokelela ekwenziweni kwepolymer ephezulu yemolekyuli nge-photosensitive polymerization.

- Uphuhliso: Isisombululo se-sodium carbonate kwi-inki e-unpolymerized iyasuswa.

- I-Post-baking: I-inki iqiniswe ngokupheleleyo.

10. Ushicilelo Lombhalo: Eli nyathelo libandakanya ukuprintwa okubhaliweyo kwibhodi yePCB ukuze kube lula ukubhekisela kuyo ngexesha leenkqubo zokuthengisela ezilandelayo.

- Pickling: Umphezulu webhodi uyacocwa ukususa i-oxidation kunye nokuphucula ukunamathela kwe-inki yokushicilela.

- Ushicilelo Lombhalo: Umbhalo ofunekayo uprintwe ukuququzelela iinkqubo zokuwelda ezilandelayo.

I-11.Unyango olungaphezulu: Ipleyiti yobhedu engenanto iphathwa ngokusekwe kwiimfuno zabathengi (ezifana ne-ENIG, HASL, Silver, Tin, Plating gold, OSP) ukukhusela i-rust kunye ne-oxidation.

I-12.Iprofayili yeBhodi: Ibhodi ibunjwe ngokweemfuno zomthengi, iququzelela i-SMT patching kunye nendibano.

14. Ukuhlolwa koMgangatho wokugqibela (FQC): Uhlolo olubanzi lwenziwa emva kokugqiba zonke iinkqubo.