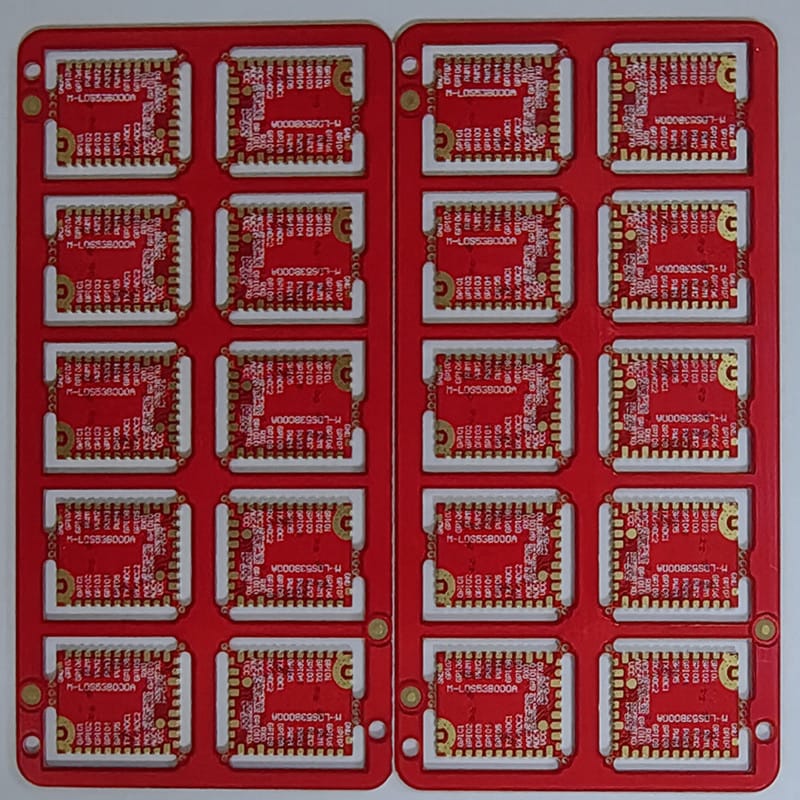

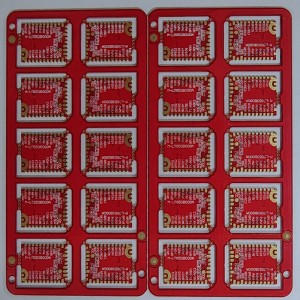

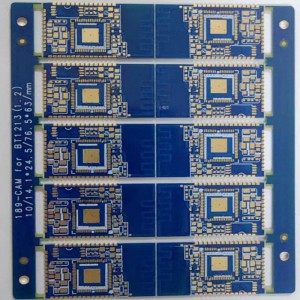

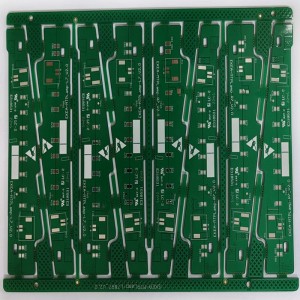

Iibhodi zesekethe eprintiweyo RED solder imaski imingxuma castela

Inkcazo yeMveliso:

| Izinto ezisisiseko: | FR4 TG140 |

| Ukutyeba kwePCB: | 1.0+/-10% mm |

| Ubalo lomaleko: | 4L |

| Ukutyeba kobhedu: | 1/1/1/1 oz |

| Unyango lomphezulu: | ENIG 2U” |

| Imaski yeSolder: | Ubomvu obukhazimlayo |

| Isikrini sesilika: | Mhlophe |

| Inkqubo ekhethekileyo : | Pth isiqingatha semingxuma emiphethweni |

Isicelo

Iinkqubo zemingxunya enesiqingatha ezicandiweyo zezi:

1. Yenza umngxuma wesiqingatha secala kunye nesixhobo sokusika esine-V kabini.

2. I-drill yesibini yongeza imingxuma yesikhokelo kwicala lomngxuma, isusa ulusu lobhedu kwangaphambili, inciphisa i-burrs, kwaye isebenzisa ii-groove cutters endaweni ye-drills ukuze kulungiswe isantya kunye nokulahla isantya.

3. Gxininisa ubhedu kwi-electroplate i-substrate, ukwenzela ukuba umaleko wobhedu ufakwe kwi-electroplated eludongeni lomngxuma womngxuma ojikelezayo kumda webhodi.

4. Ukuveliswa kwesekethe yangaphandle yomaleko emva kokulanyiswa, ukuvezwa, kunye nophuhliso lwe-substrate ngokulandelelana, i-substrate ixhomekeke kwi-plating yobhedu yesibini kunye ne-tin plating, ukwenzela ukuba umaleko wobhedu kudonga lomngxuma womngxuma ojikelezayo kumphetho webhodi uqiniswe kwaye umaleko wobhedu ugutyungelwe ngumaleko we-tin ukuxhathisa ukubola;

5. Ukwenza umngxuma wesiqingatha unqumle umngxuma ojikelezayo kumda webhodi kwisiqingatha ukwenza umngxuma;

6. Kwisinyathelo sokususa ifilimu, ifilimu ye-anti-electroplating ecinezelekileyo ngexesha lenkqubo yokucofa ifilimu iyasuswa;

7. Ukubethelwa kwe-substrate kufakwe, kwaye ubhedu oluvezwayo kuluhlu lwangaphandle lwe-substrate lususwe ngokucofa;

8. I-tin ehlutha i-substrate ihluthwe i-tin, ukwenzela ukuba i-tin eludongeni lwe-half-hole ingasuswa, kwaye ubhedu oluseludongeni lwe-half-hole lubonakaliswe.

9. Emva kokwenza, sebenzisa iteyiphu ebomvu ukuncamathelisa iibhodi zeyunithi kunye, kwaye ususe iibhula ngomgca we-alkaline etching.

10. Emva kokutyalwa kobhedu okwesibini kunye ne-tin kwi-substrate, umngxuma ojikelezileyo kumphetho webhodi unqunyulwe kwisiqingatha ukwenza isiqingatha somngxuma, ngenxa yokuba umaleko wobhedu wodonga lomngxuma ugutyungelwe ngumaleko we-tin, kwaye umaleko wobhedu wodonga lomngxuma ulungelelene ngokupheleleyo kunye nomaleko wobhedu womaleko ongaphandle we-substrate enokuthi ithintele i-copper Connection, enokuthi ithintele i-copper Connection. udonga lomngxuma ekutsalweni okanye ukuphoswa kobhedu xa usikwa;

11. Emva kokuba kugqitywe ukubunjwa kwesiqingatha somngxuma, ifilimu iyasuswa kwaye igxininiswe, ukwenzela ukuba umphezulu wobhedu awuyi kuba ne-oxidized, ngokufanelekileyo ukuphepha ukwenzeka kobhedu olushiyekileyo okanye isiphaluka esifutshane, kunye nokuphucula izinga lesivuno sebhodi yesekethe ye-PCB enesiqingatha somngxuma.

Ii-FAQs

I-half-hole efakwe kwi-half-hole okanye i-castelated-hole, i-edge enesitampu ngokusikwa kwisiqingatha kulwandlalo. I-Plated half-hole yinqanaba eliphezulu leengqungquthela ezifakwe kwiibhodi zeesekethe eziprintiweyo, ezidla ngokusetyenziselwa ukudibanisa ibhodi ukuya kwibhodi.

I-Via isetyenziswa njengonxibelelwano phakathi kweemaleko zobhedu kwi-PCB ngelixa i-PTH isenziwa ngokubanzi ibe nkulu kune-vias kwaye isetyenziswa njengomngxuma ocandiweyo wokwamkelwa kwecandelo elikhokelayo - njenge-non-SMT resistors, capacitors, kunye nephakheji ye-DIP IC. I-PTH isenokusetyenziswa njengemingxuma yoqhagamshelo ngoomatshini ngelixa i-vias ayinakho.

I-plating kwimingxunya ilubhedu, i-conductor, ngoko ivumela ukuhanjiswa kombane ukuhamba ngebhodi. I-non-plated ngokusebenzisa imingxuma ayinayo i-conductivity, ngoko ke ukuba uyayisebenzisa, unokuba neengoma zobhedu eziluncedo kwelinye icala lebhodi.

Kukho iintlobo ezi-3 zemingxuma kwi-PCB, iPlated through Hole (PTH), i-Non-Plated through Hole (NPTH) kunye ne-Via Holes, ezi akufanele zidideke kunye ne-Slots okanye i-Cut-outs.

Ukusuka kumgangatho we-IPC, yi +/-0.08mm ye-pth, kunye +/-0.05mm ye-npth.