Izixhobo zelabhoratri eziphathekayo nezekhemikhali:

Uvavanyo lomatshini, uvavanyo lombane, ukuhlolwa kwebhodi yokuqala kunye novavanyo, uhlalutyo lwebhubhoratri.

1. I-copper foil tensile tester: Esi sixhobo sisetyenziselwa ukulinganisa amandla e-tensile ye-foil yobhedu ngexesha lenkqubo yokwelula. Inceda ukuvavanya amandla kunye nokuqina kwe-foil yobhedu ukuqinisekisa umgangatho wemveliso kunye nokuthembeka.

I-Copper Foil Tensile Tester

Umatshini woVavanyo lwesitshizi seTyuwa ngokuZenzeka ngokupheleleyo

2. Umatshini wokuvavanya ityuwa yokutshiza ngokuzeleyo ngokuzenzekelayo: Lo matshini ulinganisa indawo yokutshiza ityuwa ukuvavanya ukuxhathisa kokubola kweebhodi zesekethe emva konyango lomphezulu. Inceda ukulawula umgangatho wemveliso kunye nokuqinisekisa ukusebenza okuzinzileyo kwiindawo ezinzima.

3. Umatshini wokuvavanya ucingo olune: Esi sixhobo sivavanya ukuxhathisa kunye nokuhamba kweengcingo kwiibhodi zeesekethe eziprintiweyo. Ivavanya ukusebenza kombane webhodi, kubandakanywa ukusebenza kokuhanjiswa kunye nokusetyenziswa kwamandla, ukuqinisekisa uxhulumaniso oluthembekileyo noluzinzile.

Umatshini woVavanyo lweengcingo ezine

4. Umvavanyi we-Impedans: sisixhobo esibalulekileyo kwimveliso yebhodi yesekethe eprintiweyo. Isetyenziselwa ukulinganisa ixabiso le-impedance kwibhodi yesiphaluka ngokuvelisa i-fixed-frequency AC signal edlula kwisiphaluka phantsi kovavanyo. Isekethe yokulinganisa ke ibala ixabiso le-impedance ngokusekelwe kumthetho we-Ohm kunye neempawu zeesekethe ze-AC. Oku kuqinisekisa ukuba ibhodi yesekethe eveliswayo ihlangabezana neemfuno ze-impedance ezibekwe ngumthengi.

Abavelisi banokusebenzisa le nkqubo yokuvavanya ukwenza uphuculo lwenkqubo kunye nokuphucula amandla okulawula i-impedance kwiibhodi zesekethe. Oku kuyimfuneko ukuhlangabezana neemfuno zesantya esiphezulu sosasazo lwedijithali kunye nosetyenziso lwamaza kanomathotholo.

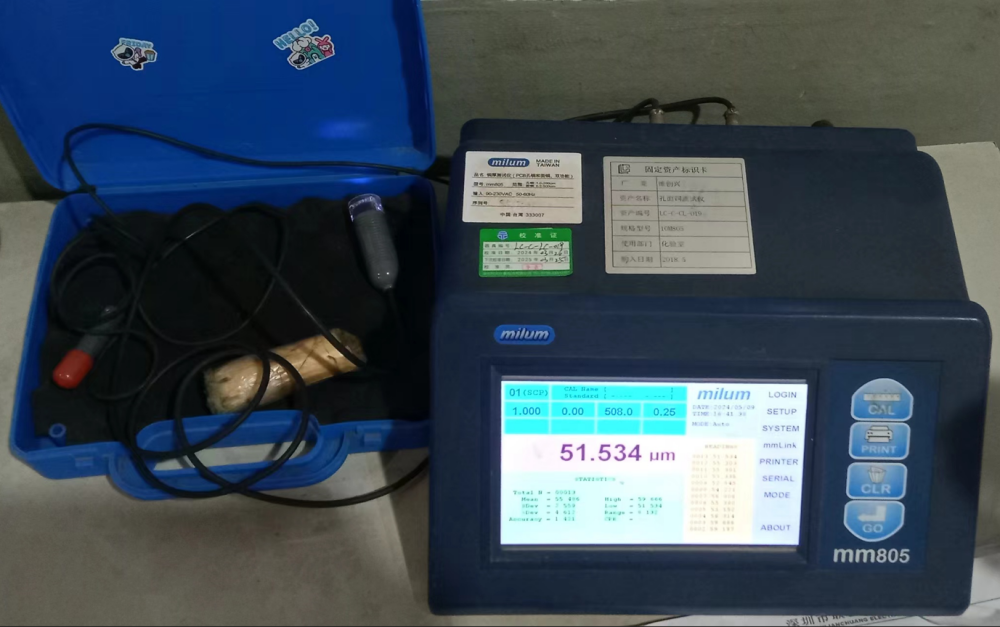

Impedance Tester

Kuyo yonke inkqubo yokuvelisa ibhodi yesekethe, uvavanyo lwe-impedance lwenziwa kumanqanaba ahlukeneyo:

1) Inqanaba loyilo: Iinjineli zisebenzisa isoftware yokulinganisa i-electromagnetic ukuyila kunye nokubeka ibhodi yesekethe. Babala kwangaphambili kwaye balinganisa amaxabiso e-impedance ukuqinisekisa ukuba uyilo luhlangabezana neemfuno ezithile. Olu faniso lunceda ukuvavanya ukungasebenzi kwebhodi yesekethe ngaphambi kokuvelisa.

I-2) Inqanaba lokuqala lokuvelisa: Ngexesha lokuveliswa kweprototype, uvavanyo lwe-impedance luyenziwa ukuze kuqinisekiswe ukuba ixabiso le-impedance lihambelana nokulindelweyo. Uhlengahlengiso kwinkqubo yokwenziwa kwemveliso lunokwenziwa ngokusekelwe kwezi ziphumo.

I-3) Inkqubo yokuvelisa: Kwimveliso yeebhodi zesekethe ezinamanqwanqwa amaninzi, uvavanyo lwe-impedance luqhutywa kwiindawo ezibalulekileyo ukuze kuqinisekiswe ukulawula iiparitha ezifana nobukhulu be-foil yobhedu, ubukhulu bezinto ze-dielectric, kunye nobubanzi bomgca. Oku kuqinisekisa ukuba ixabiso lokugqibela le-impedance lihlangabezana neemfuno zoyilo.

I-4) Ukuhlolwa kwemveliso egqityiweyo: Emva kokuveliswa, uvavanyo lokugqibela lwe-impedance lwenziwa kwibhodi yesiphaluka. Oku kuqinisekisa ukuba ulawulo kunye nohlengahlengiso olwenziwe kuyo yonke inkqubo yokuvelisa ngokufanelekileyo luhlangabezana neemfuno zoyilo lwexabiso le-impedance.

5. Umatshini wokuvavanya ukuchasana okuphantsi: Lo matshini uvavanya ukuchasana kweengcingo kunye namanqaku oqhagamshelwano kwibhodi yesiphaluka ukuqinisekisa ukuba bayahlangabezana neemfuno zoyilo kunye nokuqinisekisa umgangatho wemveliso kunye nokusebenza.

Umatshini woVavanyo oluphantsi lokuxhathisa

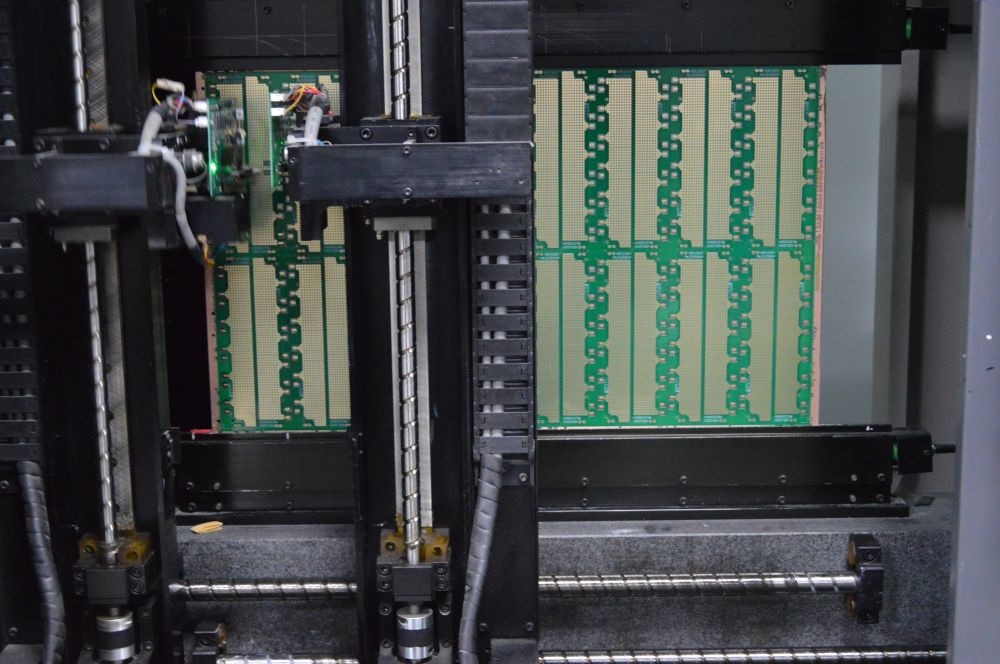

Flying Probe Tester

6. I-Flying probe tester: I-flying probe tester isetyenziselwa ukuvavanya i-insulation kunye ne-conductivity values yeebhodi zeesekethe. Iyakwazi ukubeka iliso kwinkqubo yokuvavanya kwaye ibone amanqaku eempazamo ngexesha langempela, iqinisekisa uvavanyo oluchanekileyo. Uvavanyo lwe-Flying probe lufanelekile kuvavanyo lwebhodi yesekethe yebhetshi encinci naphakathi, njengoko kuphelisa imfuno yovavanyo lokuvavanya, ukunciphisa ixesha lokuvelisa kunye neendleko.

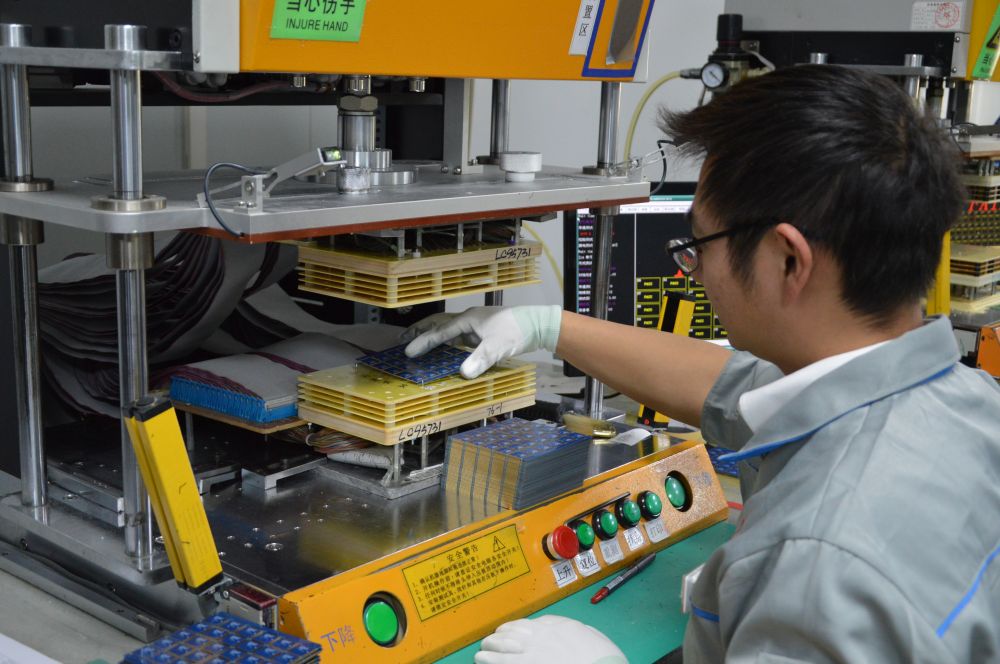

7. Umvavanyi wesixhobo sokulungisa: Ngokufana novavanyo lwe-flying probe, uvavanyo lwe-rack rack lusetyenziswa ngokuqhelekileyo kuvavanyo lwebhodi yesekethe ephakathi kunye nenkulu. Ivumela uvavanyo lwangaxeshanye lwamanqaku ovavanyo amaninzi, iphucula kakhulu impumelelo yovavanyo kunye nokunciphisa ixesha lovavanyo. Oku kwandisa imveliso yonke yomgca wemveliso, ngelixa uqinisekisa ngokuchanekileyo kunye nokusebenziseka kwakhona okuphezulu.

UMvavanyi wesixhobo sokuLungiselela iMisebenzi

I-Automatic Fixture Tooling Tester

Fixture Toolings Store

8. Isixhobo sokulinganisa esinemigangatho emibini: Esi sixhobo sithatha imifanekiso yobuso bento ngokukhanyisa nokufota. Emva koko iqhuba imifanekiso kwaye ihlalutye idatha ukufumana ulwazi lwejometri malunga nento. Iziphumo ziboniswa ngokubonakalayo, zivumela abaqhubi ukuba bajonge kwaye balinganise ngokuchanekileyo imilo, ubukhulu, indawo, kunye nezinye iimpawu zento.

Isixhobo sokulinganisa esinemigangatho emibini

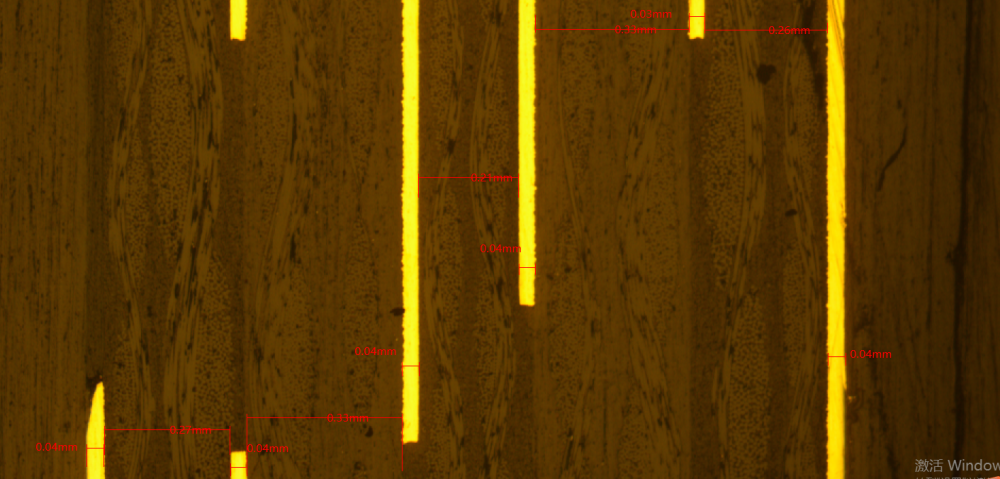

Isixhobo sokulinganisa Ububanzi bomgca

9. Isixhobo sokulinganisa ububanzi bomgca womgca: Isixhobo sokulinganisa ububanzi bomgca sisetyenziselwa ukulinganisa ububanzi obuphezulu nangaphantsi, indawo, i-angle, isangqa sesangqa, umgama weziko lesangqa, kunye nezinye iiparitha zeemveliso ezigqityiweyo zebhodi yesekethe eprintiweyo emva kophuhliso kunye ne-etching (ngaphambi kokushicilela inki ye-solder mask). Isebenzisa umthombo wokukhanya ukukhanyisa ibhodi yesekethe kwaye ibambe isignali yomfanekiso ngokusebenzisa i-optical amplification kunye neCCD photoelectric signal conversion. Iziphumo zomlinganiselo ziboniswa kwi-interface yekhompyutheni, evumela umlinganiselo ochanekileyo kunye nofanelekileyo ngokucofa umfanekiso.

10. Isithando somlilo: Isithando somlilo sisetyenziselwa ukuvavanya ukunyamezela kunye nokuxhatshazwa kwe-thermal kwiibhodi zeesekethe, ukuqinisekisa umgangatho kunye nokuthembeka kwamalungu e-solder.

Uvavanyo lwe-Solderability: Oku kuvavanya ukukwazi komphezulu webhodi yesekethe ukwenza iibhondi ze-solder ezithembekileyo. Ilinganisa iindawo zoqhagamshelwano ukuvavanya ukudibanisa phakathi kwezinto ezithengiswayo kunye nomgangatho webhodi yesekethe.

Uvavanyo lokuxhathisa ukothuka kwe-Thermal: Olu vavanyo luvavanya ukuxhathisa kwebhodi yesekethe kwiiyantlukwano zobushushu kwiindawo ezinobushushu obuphezulu. Kubandakanya ukuveza ibhodi yesekethe kumaqondo obushushu aphezulu kwaye ngokukhawuleza uyidlulisele kumaqondo obushushu asezantsi ukuvavanya ukuxhathisa kwe-thermal shock.

11. Umatshini wokuhlola i-X-Ray: Umatshini wokuhlola i-X-ray unako ukungena kwiibhodi zeesekethe ngaphandle kwesidingo sokuqhawula okanye ukubangela umonakalo, ngaloo ndlela ugwema iindleko kunye nomonakalo. Iyakwazi ukubona iziphene kwibhodi yesiphaluka, kubandakanywa imingxuma ye-bubble, iisekethe ezivulekileyo, iisekethe ezimfutshane, kunye nemigca ephosakeleyo. Isixhobo sisebenza ngokuzimeleyo, ukulayisha ngokuzenzekelayo kunye nokukhulula izinto eziphathekayo, ukufumanisa, ukuhlalutya, kunye nokumisela izinto ezingaqhelekanga, kunye nokumakisha ngokuzenzekelayo kunye nokubhala, ngaloo ndlela kuphuculwe ukusebenza kakuhle kwemveliso.

Umatshini wokuhlola i-X-Ray

Ukulinganisa ukutyeba kokutyabeka

12. Igeyiji yobungakanani bokugquma: Ngexesha lenkqubo yokwenziwa kweebhodi zeesekethe, iintlobo ezahlukeneyo zokwaleka (ezifana ne-tin plating, iplating yegolide, njl.njl.) zihlala zisetyenziswa ukunyusa umgangatho we-conductivity kunye nokumelana nokubola. Nangona kunjalo, ubukhulu bokutya obungafanelekanga bunokukhokelela kwimicimbi yokusebenza. Igeyiji yobungakanani bokutyamba isetyenziselwa ukulinganisa ubukhulu bengubo kwindawo yebhodi yesekethe, iqinisekisa ukuba iyahlangabezana neemfuno zoyilo.

13. Isixhobo se-ROHS: Ekuveliseni iibhodi zeesekethe eziprintiweyo, izixhobo ze-ROHS ziqeshwe ukufumanisa nokuhlalutya izinto ezinobungozi kwizinto eziphathekayo, ukuqinisekisa ukuthotyelwa kweemfuno zomyalelo we-ROHS. Umyalelo we-ROHS, ophunyezwe yiManyano yaseYurophu, unqanda izinto eziyingozi kwizixhobo zombane kunye nezombane, kubandakanya ilothe, i-mercury, i-cadmium, i-hexavalent chromium, kunye nezinye. Izixhobo ze-ROHS zisetyenziselwa ukulinganisa umxholo wezi zinto ezinobungozi, ukuqinisekisa ukuba izinto ezisetyenziselwa inkqubo yokuvelisa iibhodi zeesekethe eziprintiweyo zihlangabezana neemfuno zomyalelo we-ROHS, ukuqinisekisa ukhuseleko lwemveliso kunye nokukhuselwa kwendalo.

Isixhobo se-ROHS

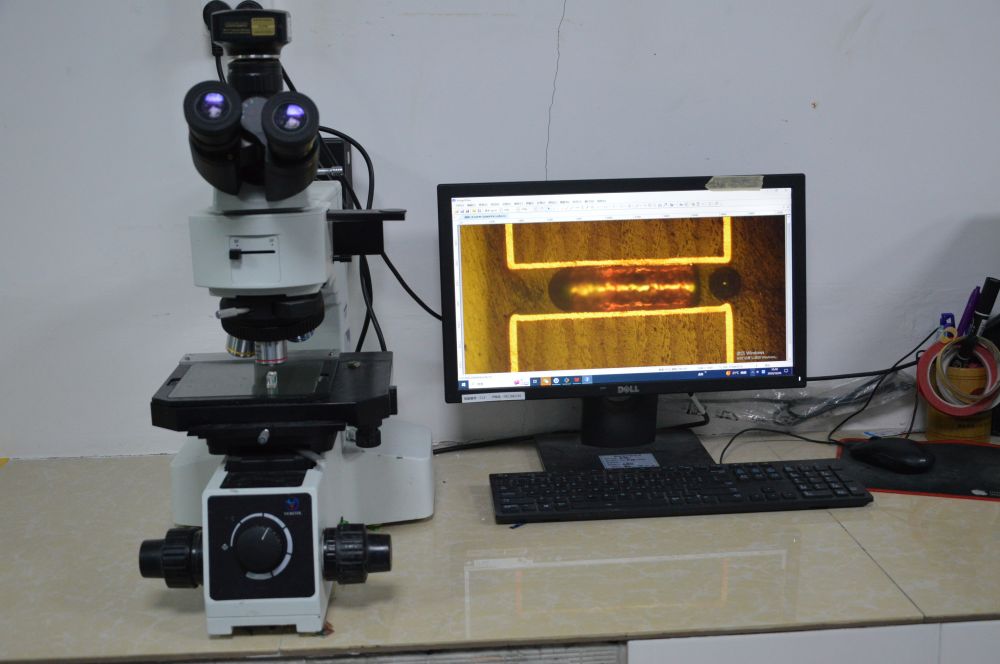

14. I-microscope ye-Metallographic: I-metallographic microscope isetyenziselwa ukuhlola ubukhulu bobhedu bemigangatho yangaphakathi nangaphandle, i-electroplated surfaces, imingxuma ene-electroplated, iimaski ze-solder, unyango lwe-surface, kunye nobukhulu be-dielectric layer nganye ukuhlangabezana neenkcukacha zabathengi.

IVenkile yeCandelo leMicroscopic

ICandelo loku-1 leMikroskopu

ICandelo lesi-2 leMikroskopu

Umngxuma Surface Copper Tester

15. Umhloli wobhedu womngxuma: Esi sixhobo sisetyenziselwa ukuvavanya ubukhulu kunye nokufana kwefoyile yobhedu kwimingxuma yeebhodi zeesekethe eziprintiweyo. Ngokuchonga ngokukhawuleza ubukhulu bobhedu obungalinganiyo okanye ukuphambuka kuluhlu oluchaziweyo, uhlengahlengiso lunokwenziwa kwinkqubo yokuvelisa ngexesha elifanelekileyo.

16. I-AOI Scanner, imfutshane ye-Automated Optical Inspection, luhlobo lwesixhobo esisebenzisa iteknoloji ye-optical ukuchonga ngokuzenzekelayo amacandelo okanye iimveliso ze-elektroniki. Ukusebenza kwayo kubandakanya ukubamba umfanekiso ongaphezulu wento phantsi kokuhlolwa usebenzisa inkqubo yekhamera enesisombululo esiphezulu. Emva koko, iteknoloji yokucubungula umfanekiso wekhompyutheni isetyenziselwe ukuhlalutya nokuthelekisa umfanekiso, okwenza ukuba kubonwe iziphene zomhlaba kunye nemiba yomonakalo kwinto ekujoliswe kuyo.

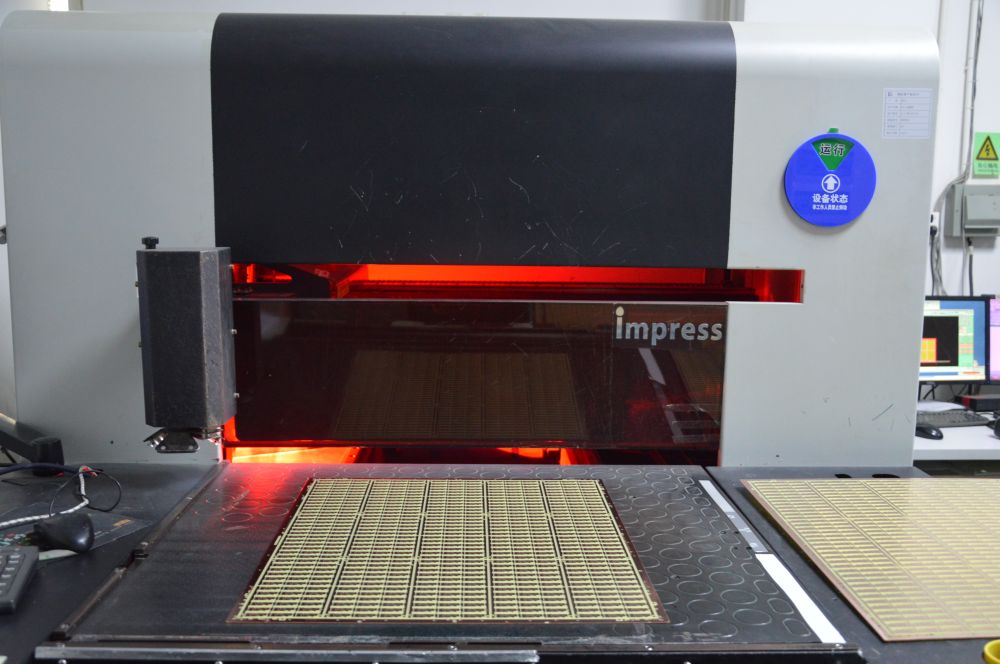

Iskena se-AOI

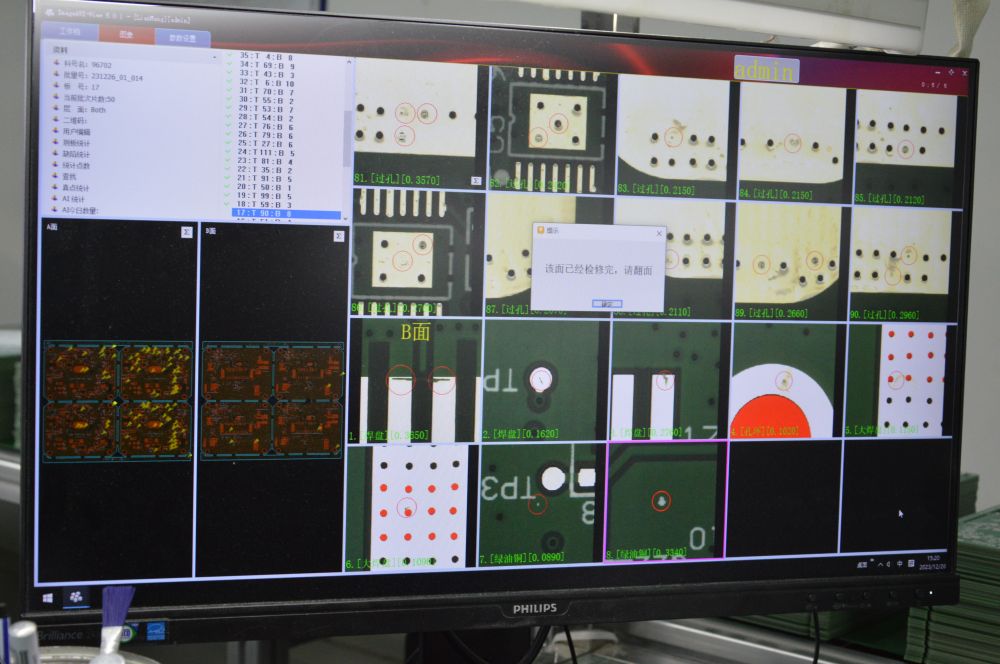

17. Umatshini wokuhlola imbonakalo yePCB sisixhobo esenzelwe ukuvavanya umgangatho wokubonwa kweebhodi zeesekethe kunye nokuchonga iziphene zokuvelisa. Lo matshini unekhamera enesisombululo esiphezulu kunye nomthombo wokukhanya wokuqhuba uviwo olucokisekileyo lomphezulu we-PCB, ukufumanisa iziphene ezahlukeneyo ezifana nemikrwelo, umhlwa, ungcoliseko, kunye nemiba ye-welding. Ngokuqhelekileyo, ibandakanya ukutya okuzenzekelayo kunye neenkqubo zokukhulula ukulawula iibhetshi ezinkulu zePCB kunye nokwahlula iibhodi ezivunyiweyo nezikhatywayo. Ngokusebenzisa i-algorithms yokucwangcisa imifanekiso, iziphene ezichongiweyo zihlelwa kwaye ziphawulwe, ziququzelele ukulungiswa okulula kunye nokuchaneka ngakumbi okanye ukupheliswa. Enkosi kwi-automation kunye nobuchule obuphezulu bokwenza imifanekiso, aba matshini benza uhlolo ngokukhawuleza, bexhasa imveliso kunye nokucutha iindleko. Ngaphaya koko, banokugcina iziphumo zohlolo kwaye bavelise iingxelo ezineenkcukacha zokujongwa komgangatho kunye nokuphucula inkqubo, ekugqibeleni baphakamise umgangatho wemveliso..

Umatshini wokuhlola imbonakalo 1

Umatshini wokuhlola imbonakalo 2

Imbonakalo yoHlolo lweziphene eziphawulweyo

PCB Consumination Tester

18. I-PCB ion contamination tester sisixhobo esikhethekileyo esisetyenziselwa ukuchonga ungcoliseko lwe-ion kwiibhodi zesekethe eziprintiweyo (PCBs). Ngexesha lenkqubo yokwenziwa kombane, ubukho beeyoni kumphezulu wePCB okanye ngaphakathi kwebhodi bunokuchaphazela kakhulu ukusebenza kwesekethe kunye nomgangatho wemveliso. Kungoko, uvavanyo oluchanekileyo lwamanqanaba ongcoliseko lwe-ion kwiiPCBs lubalulekile ukuqinisekisa umgangatho kunye nokuthembeka kwempahla yombane.

19. Umatshini wokuvavanya ukugquma kwe-voltage osebenzayo usetyenziselwa ukuqhuba i-insulation ukumelana novavanyo lwe-voltage ukuqinisekisa ukuba imathiriyeli yokugquma kunye noyilo lwesakhiwo sebhodi yesekethe ihambelana neenkcukacha eziqhelekileyo. Oku kuqinisekisa ukuba ibhodi yesekethe ihlala ikhuselwe phantsi kweemeko zokusebenza rhoqo, ukuthintela ukusilela okunokuthi kuholele kwiziganeko eziyingozi. Ngokuhlalutya iziphumo zovavanyo, nayiphi na imiba esisiseko yebhodi yesekethe inokuchongwa ngokukhawuleza, ikhokela abayili ekwandiseni uyilo lwebhodi kunye nolwakhiwo lokugquma ukunyusa umgangatho kunye nokusebenza kwayo.

Umatshini woVavanyo lwe-Voltage Insulation

I-UV Spectrophotometer

20. I-spectrophotometer ye-UV: I-spectrophotometer ye-UV isetyenziselwa ukulinganisa iimpawu zokufunxa ukukhanya kwemathiriyeli ye-photosensitive esetyenziswe kwiibhodi zesekethe. Ezi zixhobo, ngokuqhelekileyo i-photoresists esetyenziselwa ukuveliswa kweebhodi zeesekethe eziprintiweyo, zinoxanduva lokudala iipateni kunye nemigca kwiibhodi.

Imisebenzi ye-UV spectrophotometer ibandakanya:

I-1) Umlinganiselo weempawu zokufunxa ukukhanya kwe-photoresist: Ngokuhlalutya iimpawu zokufunxa ze-photoresist kuluhlu lwe-ultraviolet spectrum, iqondo lokufunxa ukukhanya kwe-ultraviolet kunokumiselwa. Olu lwazi lunceda ekulungiseni ukuqulunqwa kunye nobukhulu bengubo ye-photoresist ukuqinisekisa ukusebenza kwayo kunye nokuzinza ngexesha le-photolithography.

I-2) Ukumiselwa kweeparamitha zokuvezwa kwe-photolithography: Ngokuhlalutya kweempawu zokufunxa ukukhanya kwe-photoresist, i-photolithography ye-exposure parameters ye-exposure ye-photolithography, njengexesha lokuvezwa kunye nokukhanya kokukhanya, kunokumiselwa. Oku kuqinisekisa ukuphindaphindwa okuchanekileyo kweepateni kunye nemigca kwi-photoresist esuka kwibhodi yesekethe.

21. imitha ye-pH: Kwinkqubo yokuvelisa iibhodi zeesekethe, unyango lweekhemikhali ezifana ne-pickling kunye nokucoca i-alkali zisetyenziswa ngokuqhelekileyo. Imitha ye-pH isetyenziselwa ukuqinisekisa ukuba ixabiso le-pH lesisombululo sonyango lihlala ngaphakathi koluhlu olufanelekileyo. Oku kuqinisekisa ukusebenza, ukusebenza, kunye nokuzinza kwonyango lweekhemikhali, ngaloo ndlela kuphuculwe umgangatho wemveliso kunye nokuthembeka ngelixa uqinisekisa indawo yokuvelisa ekhuselekileyo.