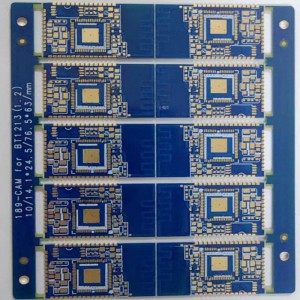

I-Pcb prototype pcb eyenziwe nge-blue solder imaski egcwele isiqingatha semingxuma

Inkcazo yeMveliso:

| Izinto ezisisiseko: | FR4 TG140 |

| Ukutyeba kwePCB: | 1.0+/-10% mm |

| Ubalo lomaleko: | 2L |

| Ukutyeba kobhedu: | 1/1 oz |

| Unyango lomphezulu: | ENIG 2U” |

| Imaski yeSolder: | Ibhlowu ekhazimlayo |

| Isikrini sesilika: | Mhlophe |

| Inkqubo ekhethekileyo : | Pth isiqingatha semingxuma emiphethweni |

Isicelo

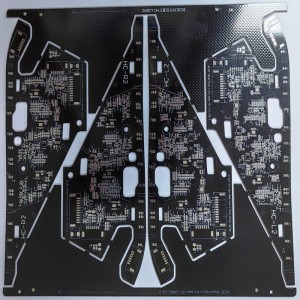

PCB isiqingatha-umngxuma ibhodi ibhekisela kukomba yesibini kunye nokumila inkqubo emva kokuba umngxuma yokuqala ibhodlo, yaye ekugqibeleni isiqingatha umngxuma metallized ebekelwe. Injongo kukudibanisa ngokuthe ngqo umda womngxuma ukuya kumda oyintloko ukugcina izihlanganisi kunye nendawo, kwaye zivame ukuvela kwiisekethe zesignali.

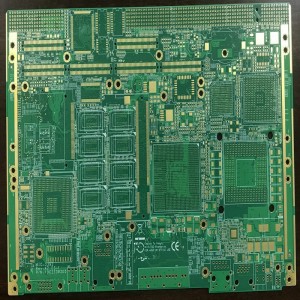

Iibhodi zeesekethe ezinesiqingatha zidla ngokusetyenziselwa ukunyuswa kwezixhobo ze-elektroniki ezinoxinzelelo oluphezulu, njengezixhobo eziphathwayo, iiwotshi ezilumkileyo, izixhobo zonyango, izixhobo zomsindo kunye nevidiyo, njl.njl. Benza ukuxinana kwesekethe ephezulu kunye neenketho zokunxibelelana ngakumbi, ukwenza izixhobo zombane zibe zincinci, zilula kwaye zisebenze ngakumbi.

Umngxuma ongafakwanga kwisiqingatha semiphetho yePCB yenye yezinto zoyilo ezisetyenziswa ngokuqhelekileyo kwinkqubo yokwenziwa kwePCB, kwaye umsebenzi wayo ophambili kukulungisa iPCB. Kwinkqubo yokuveliswa kwebhodi ye-PCB, ngokushiya imingxunya enesiqingatha kwizikhundla ezithile emphethweni webhodi ye-PCB, ibhodi ye-PCB inokulungiswa kwisixhobo okanye indlu enezikrufu. Kwangaxeshanye, ngexesha lenkqubo yendibano yebhodi yePCB, umngxuma wesiqingatha ukwanceda ukubeka nokulungelelanisa ibhodi yePCB ukuqinisekisa ukuchaneka nokuzinza kwemveliso yokugqibela.

Umngxuma wesiqingatha ofakwe kwicala lebhodi yesekethe kukuphucula ukuthembeka koqhagamshelwano lwecala lebhodi. Ngokuqhelekileyo, emva kokuba ibhodi yesekethe eprintiweyo (PCB) ilungiswe, umaleko wobhedu oveziweyo emphethweni uya kubonakaliswa, oxhomekeke kwi-oxidation kunye ne-corrosion. Ukuze ukusombulula le ngxaki, umaleko ubhedu idla iqatywe umaleko olukhuselayo ngu electroplating emphethweni webhodi ibe umngxuma isiqingatha ukuphucula ukumelana yayo oxidation kunye nokumelana umhlwa, kwaye kunokonyusa indawo welding kunye nokuphucula ukuthembeka uqhagamshelo.

Kwinkqubo yokucubungula, indlela yokulawula umgangatho wemveliso emva kokwenza imingxuma ye-semi-metallized emphethweni webhodi, njengameva obhedu eludongeni lomngxuma, njl., Isoloko iyingxaki enzima kwinkqubo yokucubungula. Ngolu hlobo lwebhodi kunye nomqolo wonke wemingxuma semi-metallized Ibhodi ye-PCB ibonakaliswe nge-diameter encinci yomngxuma, kwaye isetyenziswa kakhulu kwibhodi yentombi yebhodi yomama. Ngokusebenzisa le mingxuma, idityaniswe kunye nebhodi yomama kunye nezikhonkwane zamacandelo. Xa i-soldering, iya kukhokelela kwi-soldering ebuthathaka, i-solder yobuxoki, kunye ne-brodging short circuit phakathi kwezikhonkwane ezimbini.

Ii-FAQs

Kunokuba luncedo ukubeka imingxuma ecwecwe (PTH) kumphetho webhodi. Umzekelo xa ufuna ukuthengisa ii-PCB ezimbini kwenye enye nge-engile ye-90 ° okanye xa uthengisa i-PCB kwisingxobo sesinyithi.

Umzekelo, indibaniselwano yeemodyuli ezintsonkothileyo ze-microcontroler ezineePCB eziqhelekileyo, eziyilwe ngabanye.Usetyenziso olongezelelweyo lubonisa, i-HF okanye iimodyuli ze-ceramic ezithengiswa kwibhodi yesekethe eprintiweyo.

I-Drilling- plated ngokusebenzisa umngxuma (PTH) - i-panel plating - ukudluliselwa komfanekiso - ipateni yokubeka -i-pth isiqingatha somngxuma-ukuqhawula - i-etching - imaski ye-solder - i-silkscreen - unyango lomphezulu.

1.Ububanzi ≥0.6MM;

2.Umgama phakathi komngxuma ≥0.6MM;

3. Ububanzi be-ring etching ifuna i-0.25mm;

Umngxuma wesiqingatha yinkqubo ekhethekileyo. Ukuze kuqinisekiswe ukuba kukho ubhedu emngxunyeni, kufuneka kugalelwe kuqala phambi kokuba kubekwe ubhedu. I-PCB enesiqingatha somngxuma jikelele incinci kakhulu, ngoko ke ixabiso layo libiza kakhulu kune-PCB eqhelekileyo.